St. Regis Boosts Energy Efficiency with AI-Optimized Chiller Plant Operations

St. Regis Hotel achieved 9% energy savings and reduced reporting time by automating chiller plant operations using AI-driven optimization, fault detection, and real-time data analytics.

Location

444 Phayathai Road, Pathumwan District, Bangkok 10330

Property Type

Mixed-use

HVAC Details

Chiller Plant

Reduced Reporting Time

Automated reporting reduced the time required for preparing operational and performance reports.

Optimized Operations

Improved visibility and control of the chiller plant, ensuring efficient and cost-effective operation.

9% Energy Savings

Achieved an energy savings of approximately 9% from improved chiller plant performance and reduce energy consumption.

Client's Challenges

No Automation for Chiller Plant

The hotel relied on manual chiller plant operations, which were inefficient and costly.

Energy Inefficiency

Manual controls led to higher energy consumption, negatively impacting operational costs.

Lack of Monitoring System

Without real-time monitoring, it was difficult for the client to understand the chiller plant’s performance or quickly identify and resolve issues.

Our Solution

Chiller Plant Energy Optimization

Integrated the Alto Autopilot Chiller Plant app, utilizing AI and machine learning to optimize energy consumption and reduce carbon emissions.

Automated Reporting

Deployed the Auto Plant Report app to automate the generation of executive summary reports, reducing manual data processing time.

Fault Detection & Diagnosis (FDD)

Implemented the FDD app to detect deviations and fault conditions using machine learning for early pattern-based fault prediction.

Data Analytics Dashboard

Provided a real-time and historical data dashboard with alerts and recommendations, allowing for efficient management of energy and resource usage.

Implementation Process

1

Energy Audit

1 - 2 days

Conducted a detailed energy audit to assess the current chiller plant operations and identify savings opportunities.

2

Proposal of Alto Applications

1 week

Presented the AI-driven Alto solutions with potential energy savings projections.

3

Sensor & Hardware Installation

4 - 6 weeks

Installed necessary sensors (temperature, flow, BTU meters) and the Alto CERO Box for real-time monitoring.

4

Software Commissioning

1 week

Configured and tested the software for smooth integration.

5

Handover & Onboarding

1 week

Trained staff on system use and provided comprehensive onboarding.

6

Updates & Support

On-going

Continued system optimization and support to ensure peak performance.

Related Cases

Hotel

Boosting Efficiency and Reducing Costs: Energy Optimization for a Pattaya Hotel

This medium-sized hotel in Pattaya reduced energy costs by 1M THB annually, improved room turnaround times, and enhanced quality control.

Mixed-use

MBK Transforms Chiller Plant Efficiency with AI-Driven Optimization

MBK's mixed-use facility achieved 5M THB in annual savings, streamlined reporting, and improved tenant satisfaction by implementing solutions for chiller plant.

Hotel

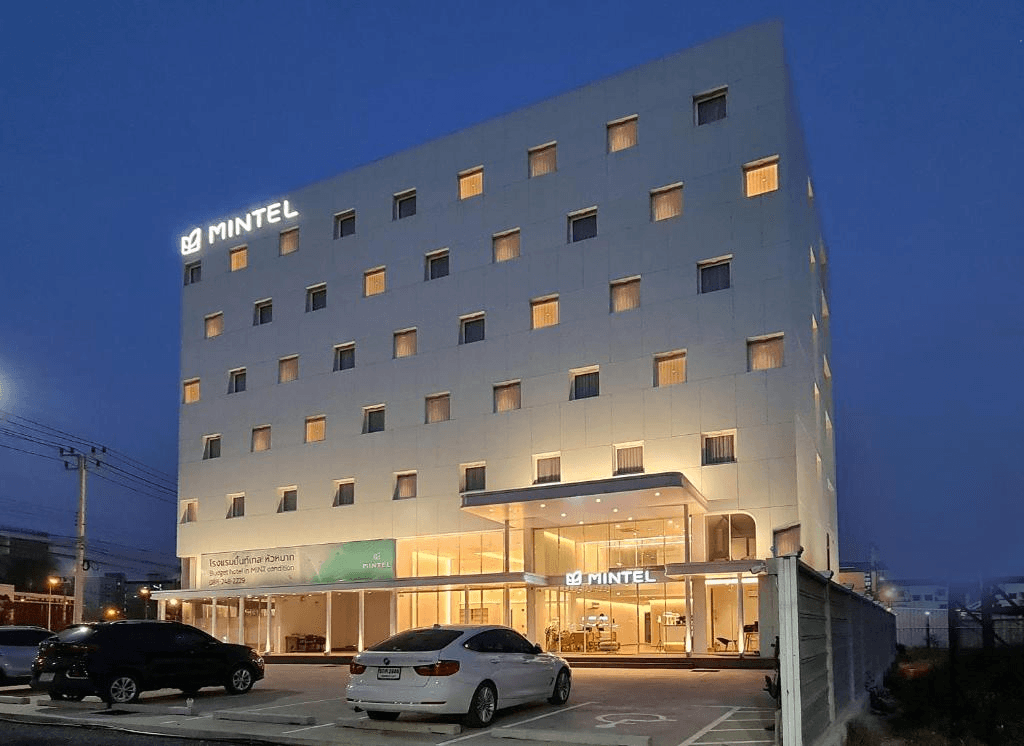

Mintel's Shift to Automation & Remote Management

Mintel Hotel cut staffing costs and enhanced guest experiences by integrating remote management and QR code-based service access.