MBK Transforms Chiller Plant Efficiency with AI-Driven Optimization

MBK's mixed-use facility achieved 15% annual savings, streamlined reporting, and improved tenant satisfaction by implementing AI-driven chiller plant optimization, fault detection, and automated reporting solutions.

Fewer Complaints

Improved environmental conditions led to fewer complaints from building visitors and tenants, enhancing their overall experience.

Reduced Reporting Time

Automated reports significantly reduced the time spent on preparing data and performance reports.

15% Annual Savings

Achieved energy cost savings of approximately 15% from baseline through AI-driven chiller plant optimization and controls.

Location

444 Phayathai Road, Pathumwan District, Bangkok 10330

Property Type

Mixed-use

HVAC Details

Chiller Plant

Client's Challenges

Lack of Automation

The chiller plant operations were entirely manual, leading to inefficiencies in energy usage and control.

Energy Inefficiency

Manual controls made it difficult to optimize the energy performance of the chiller plant, increasing operational costs.

Limited Monitoring & Diagnosis

Without a proper monitoring system, it was hard for the client to understand the real-time status of the chiller plant or identify potential problems.

Our Solution

Chiller Plant Energy Optimization

Implemented the Alto Autopilot Chiller Plant app, utilizing AI and machine learning to optimize energy consumption and reduce the carbon footprint.

Automated Reporting

Deployed the Auto Plant Report app to generate daily, weekly, and monthly executive summary reports, reducing the time spent on manual data processing.

Fault Detection & Diagnosis (FDD)

The FDD app was installed to monitor sensor data for deviations, allowing for proactive fault detection and diagnosis using machine learning algorithms.

Data Analytics Dashboard

Provided real-time and historical data analytics, along with alerts and actionable recommendations, helping the client better manage energy and resource usage.

Implementation Process

1

Energy Audit

1 - 2 days

Conducted an energy audit to assess the current condition of the chiller plant and identify optimization opportunities.

2

Proposal of Alto Applications

1 week

Presented the Alto solution, including predicted savings from energy optimization.

3

Sensor & Hardware Installation

4 - 6 weeks

Installed additional sensors (temperature, flow, BTU, digital power meter, and IAQ) and the Alto CERO Box.

4

Software Commissioning

1 week

Configured and tested the software to ensure seamless functionality.

5

Handover & Onboarding

1 week

Trained the client's team on system usage and capabilities.

6

Maintenance & Support

On-going

Provided continuous updates and support for system optimization and performance monitoring.

Related Cases

Mixed-use

Transforming VENCO Facility Management with Data-Driven Efficiency

VENCO improved energy efficiency, streamlined operations, and reduced manual tasks by using Alto Multi-property solution.

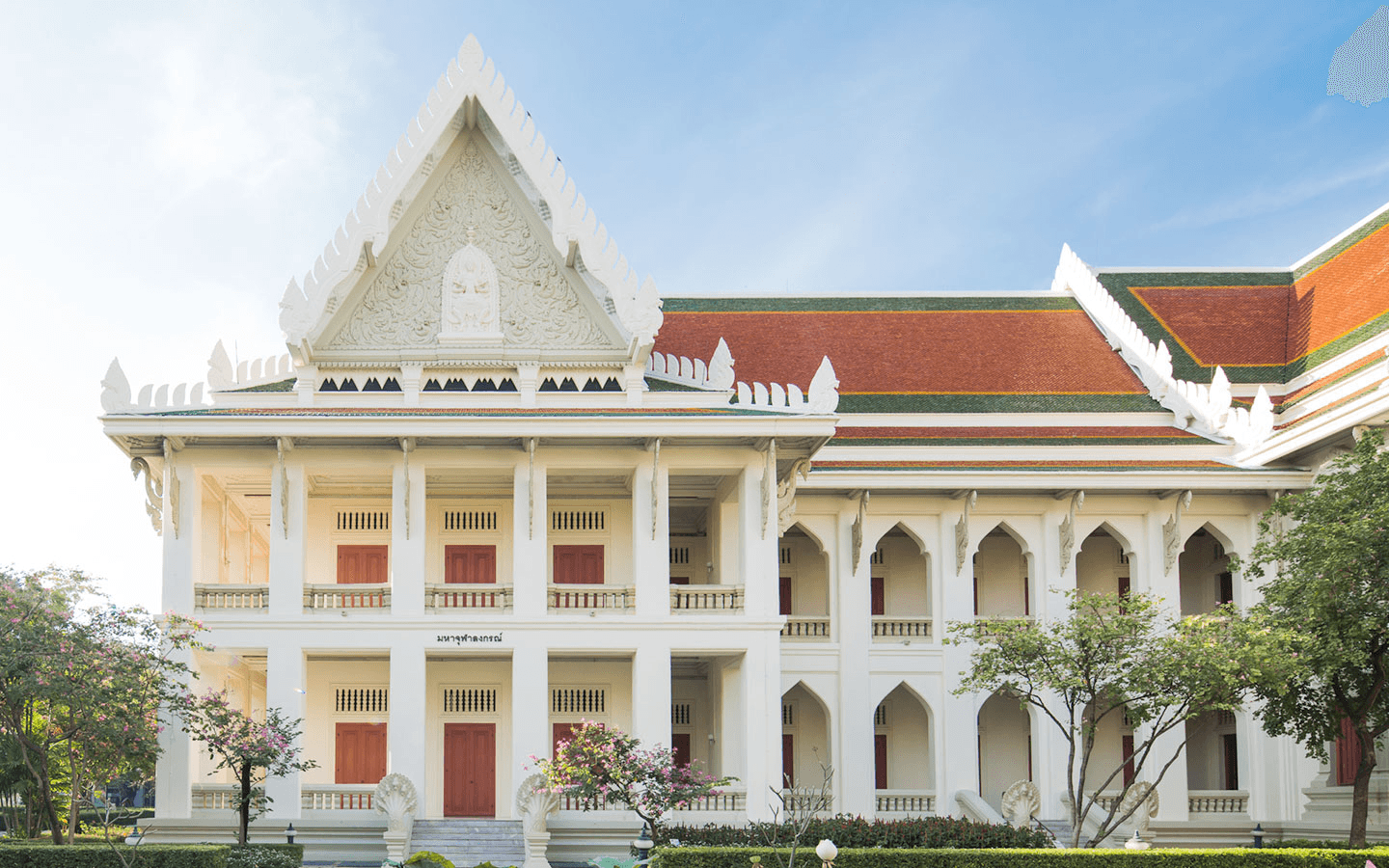

Educational

Revolutionizing Chulalongkorn Campus Operations with AI-Powered Solutions

Chulalongkorn University, one of Thailand's premier educational institutions, embarked on a transformative journey to become a "smart campus".

Government

Thai Health Promotion Foundation's Smart Dashboard

This interactive dashboard empowers users to monitor energy, waste, and carbon footprint metrics in real time, enhancing sustainability efforts across the facility.